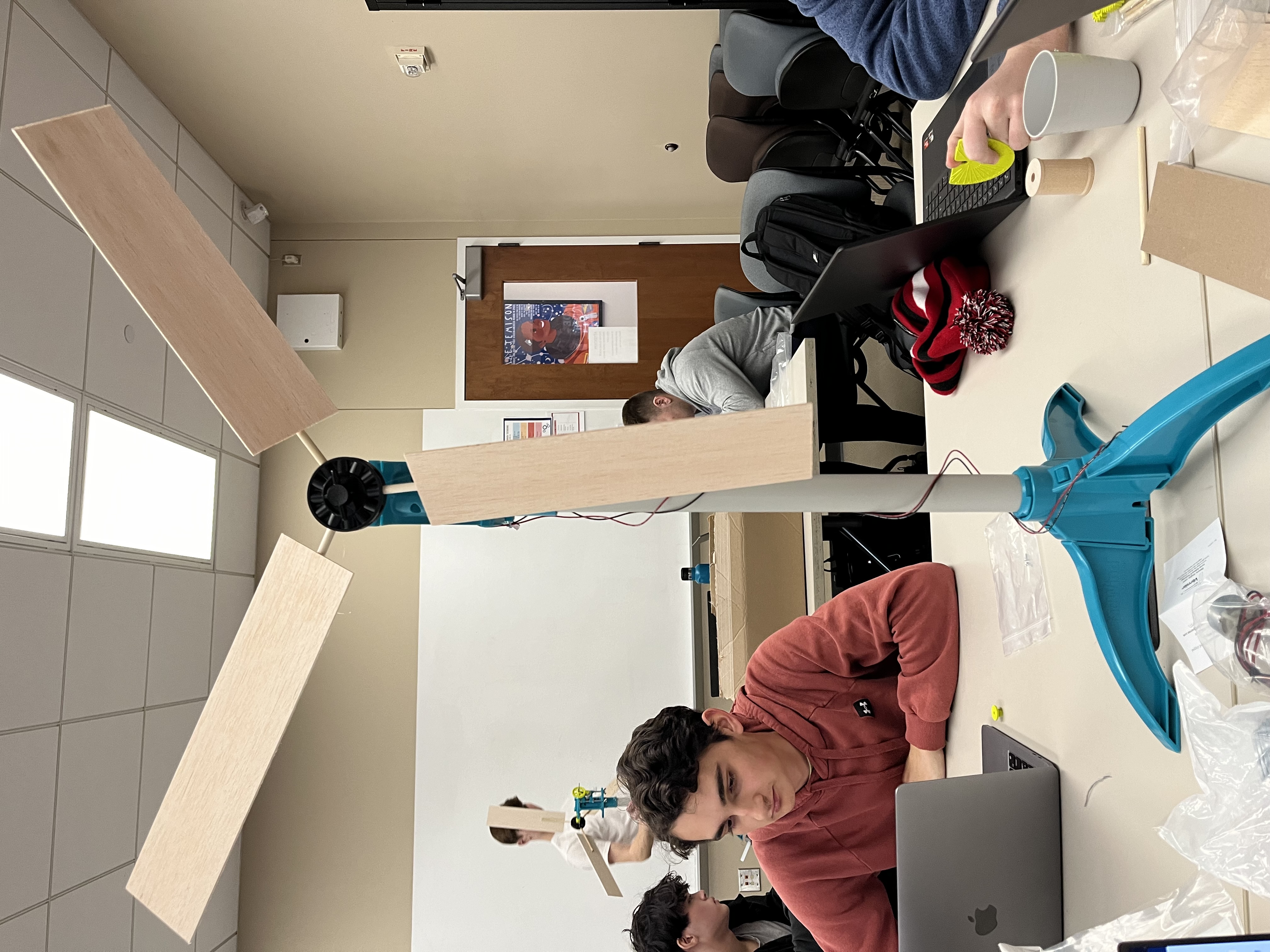

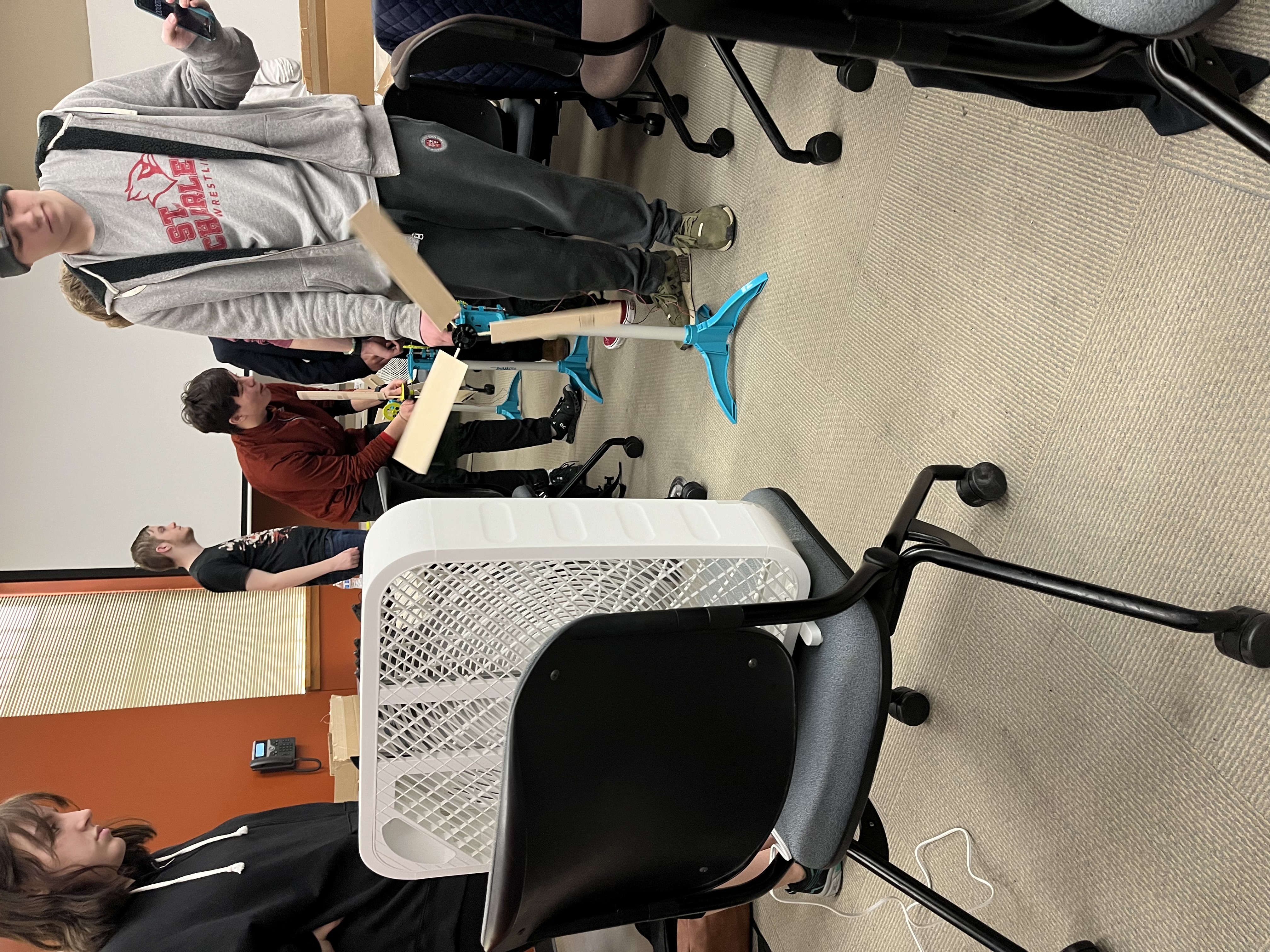

The wind turbine project’s overall goal is to generate as much power in watts as possible from the wind turbine. The dependent variable is the watt output, with the independent variable being the blade design. Our team must find the best wind turbine blade design to generate the most watts, and part of this is finding the best materials to create the blades. The project is continually creating blades to test, writing down how well they perform, and adjusting accordingly.

Our team conducted an experiment to determine which material would be the most effective to use in the final fan blade designs. The materials in question were balsa wood, cardboard, and polystyrene. We recorded the volume of each material by measuring the length, width, and height in centimeters. Afterwards, we divided the recorded masses by each volume and recorded these as the densities. As we found the measurements for each row, we then calculated the standard deviation and average. After this, we measured the power output for blades made of each material by connecting them to the turbine at a 15 degree angle. After this test, we conducted the flexion test. During this experiment, the team tested the flexibility of each material by holding the blades firmly onto the table with a specific amount hanging off, which was 18 cm.

The optimum angle for the blades is 15 degrees. At this angle, the blades spin at their fastest rate, producing the most power from spinning the turbine. When the team started increasing the angle of the blades, they noticed that the rotation speed increased, but after testing the angle of 30 degrees, they saw that the speed was starting to slow down, so they knew that the best angle for the blades was close to 15 degrees. Since starting the windmill project, the team has expanded their knowledge and learned many aspects that could improve their design. Over the last few weeks, they tested different materials for their blades and different blade angles to find the optimum efficiency for their design. During our tests, they used Balsa Wood, Cardboard, and Polystyrene as other materials to use as blades. The team found that Cardboard performed the best in most of the tests, with Balsa Wood doing similarly, while Polystyrene performed the worst out of the three.